Alfa Laval Compabloc

Introduction

The Alfa Laval Compabloc is a fully welded compact heat

exchanger designed for a wide range of process and utility

duties. The Compabloc range provides the most efficient,

cost-effective, compact and cleanable heat exchanger

solution available today. The Compabloc is the market leader

in terms of life-cycle cost and energy savings.

The heart of the Compabloc is a stack of corrugated heat

transfer plates in 316L stainless steel, or other high-grade

material. The plates are laser welded (models CP30 and

above) and form a compact core. This core is then enclosed

and supported by four corner girders, top and bottom heads

and four side panels. These components are bolted together

and can be quickly taken apart for inspection, service and

cleaning.

Applications

Thanks to the Compabloc’s unique design concept the

possibilities for process optimization and flexibility are limitless. The Compabloc can be configured in single or multi-pass arrangements in either co-current or counter-current operation, for liquid-to-liquid or two-phase duties.

For condensation and reboiling positions, the large cross flow area and short flow path fit low-pressure duties and allow very low pressure drops. For heat recovery duties, a multi-pass configuration allows temperature cross and close temperature approaches (down to 3 °C (5.4 °F)).

The design concept allows a different number of passes on the two circuits thereby enabling large differences in flow rates between the hot side and the cold side. The baffling can easily be re-arranged to suit a new duty should the flow rates or temperatures change.

The Compabloc can be mounted vertically, for normal liquid to-liquid duties, condensation with sub-cooling and gas cooling duties, or horizontally, for most condensation, reboiling or liquid-to-liquid duties where height is restricted.

Benefits

• reduced size, weight and number of heat exchangers thanks to high thermal performance and compact design • increased energy savings due to crossing temperatures and close temperature approach in a single unit

• safe handling of aggressive media and high-pressure/high temperature duties

• minimized fouling thanks to high wall shear stress • easy opening of the unit and access to the heat transfer area for facilitating inspection, mechanical cleaning, maintenance and repair

• very cost competitive design with high alloy material • reduced risk of crevice corrosion due to unique plate-to plate joints

Working principle

The two media in the Compabloc heat exchanger flow in alternately welded channels between the corrugated plates. These corrugated plates promote high turbulence which provides high heat transfer efficiency and help minimize fouling. The media flows in a cross-flow arrangement within each pass while the overall flow arrangement is counter current for a multi-pass unit (if required the unit can also be designed with overall co-current operation). Each pass is separated from the adjacent passes by a pressed baffle which forces the fluid to turn between the plate pack and the panel.

Learn more at www.alfalaval.com/compabloc

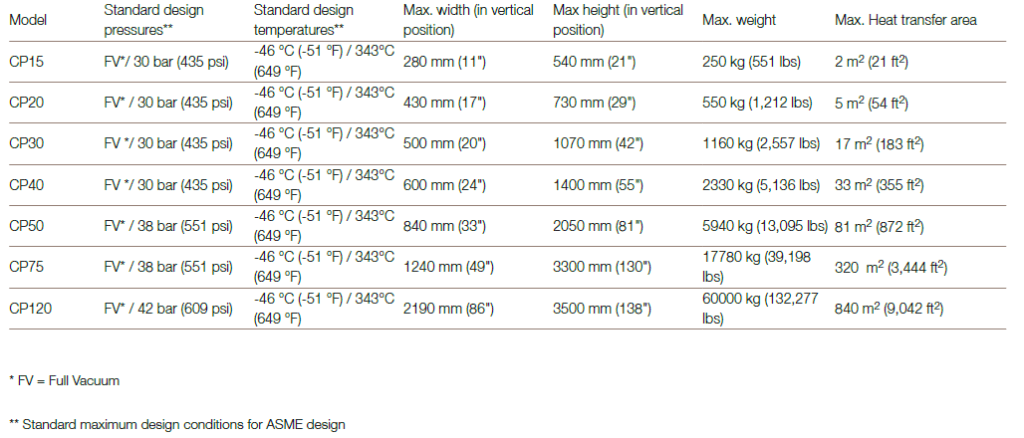

Technical data

Standard material for heat transfer plates are 316L, 254SMO,

Titanium grade 1, 904L, Alloy C276 and Alloy C22. Other

materials may be available on request.

Standard material for panels is carbon steel with lining in the

same material as plates. Other materials (like massive

stainless steel) may be available on request.

The Compabloc is available in accordance with all major

international pressure vessel codes such as ASME, PED,

etc…

The table below provides some inputs for our standard range. Other conditions may be available on request.